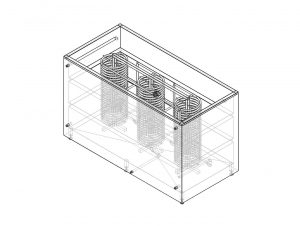

ZLV40

The Ice Water Tank ZLV with integrated copper heat exchanger (spiral) is designed for an acummulation of cold inside of the mono-propylen-glycol solution and for its subsuqent use in the processes of making, storaging and maturating of beer. The ZLV is fitted with a circulating pump for homegenization of the temperature and for the prevention of the freezing of the copper spirals, with only a minimum of power consuption.

The ZLV is standardly equipped with a single pump for circulating of the cooling solution inside the closed circuit between the brewery components and the ZLV.

If the second cooling circuit is used, the ZLV is standardly equipped with other connection points (but without a pump)

The cooling of mono-propylene glycol takes over the cooling unit VLV, which is always designed for the volume of the ice water tank. If required, one ZLV tank may have several VLV cooling units connected in series to increase the cooling performance. The recommended maximum distance of the cooling units from the ice water tank is 25 m.

The ZLV is mounted on six adjustable legs and closed by a stainless steel top cover.

Cooling solution (recommended mono-propylene glycol solution) is not included. We recommend that you deal with a food-grade liquid according to your options.

Parameters: parameters can be tailored to the needs of the customer | ||||||

| Total volume | 4 200 l | |||||

| Useful volume | 4 000 l | |||||

| Height | 1 750 mm | |||||

| Length | 1 850 mm | |||||

| Width | 1 600 mm | |||||

| Material | 1.4301 | |||||

| Polyuretan insulation | 50 mm | |||||

| Insulation surface – brushed sheet | 1.4301 | 1.1.1970 | ||||

| Water inlet 2x | DN 32 | |||||

| Water outlet | DN 40 | |||||

| Thermosensor pocket | ø10 mm | |||||

| Min. Working temperature | -15°C | |||||

| Max. working temperature | 85°C | |||||

| Drain and filling armature | DN 32 | |||||

Standart electro accessories: | ||||||

| Thermosensor | NTC | |||||

| Circulating pump | Willo | |||||

| Digital thermometer | DIXEL XR 20 D (230V 50 HZ) | |||||

| Electric switchboard: | ||||||

| Main switch | 380V 16A | |||||

| Compressor contactor | 3x230V 50 Hz 10A | |||||

| 2x motor starter | 4-6A 380V | |||||