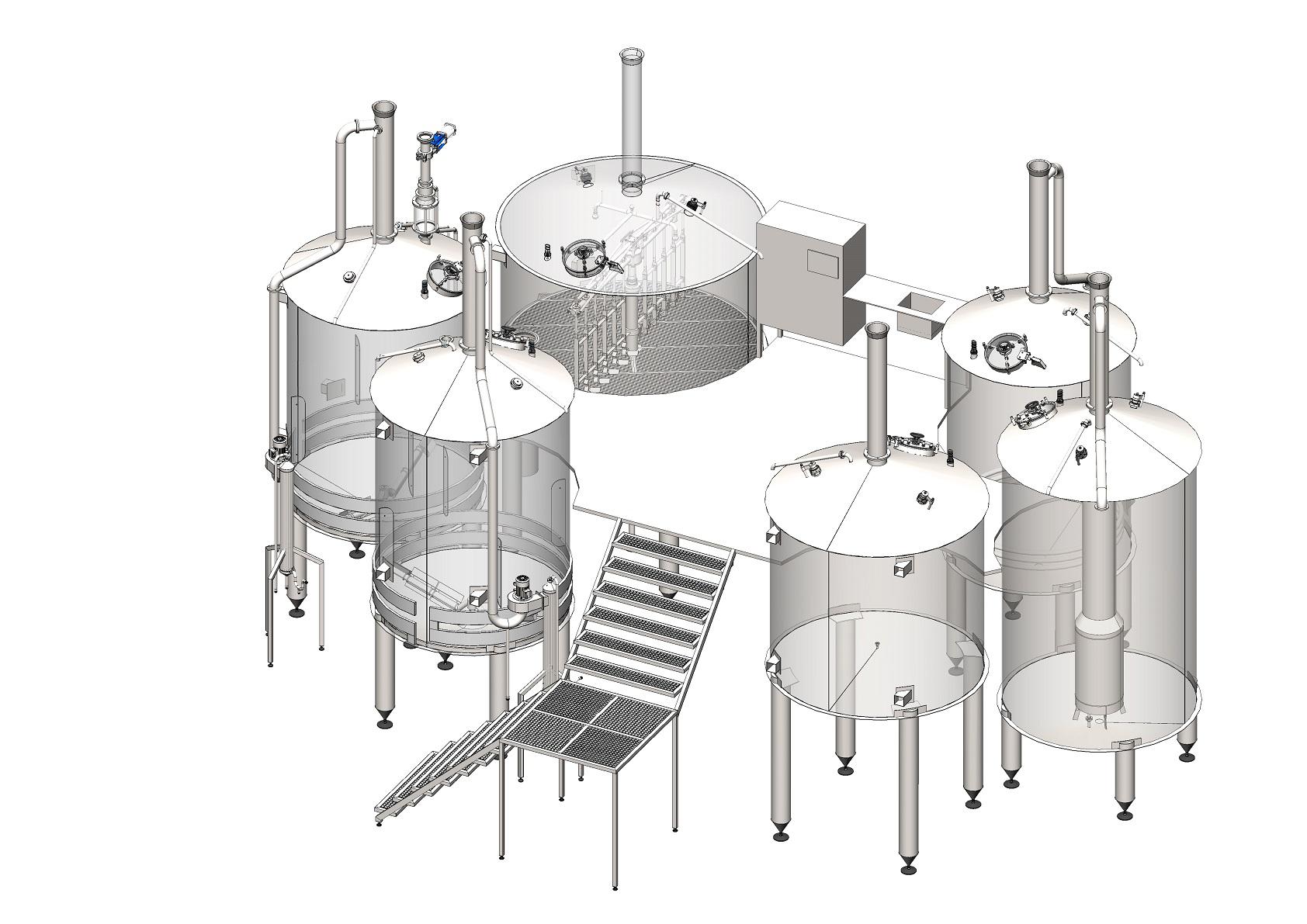

Six-vessel industrial mini-brewery

As well as the restaurant mini-breweries made by our company, also the industrial variants can be delivered in two basic variants.

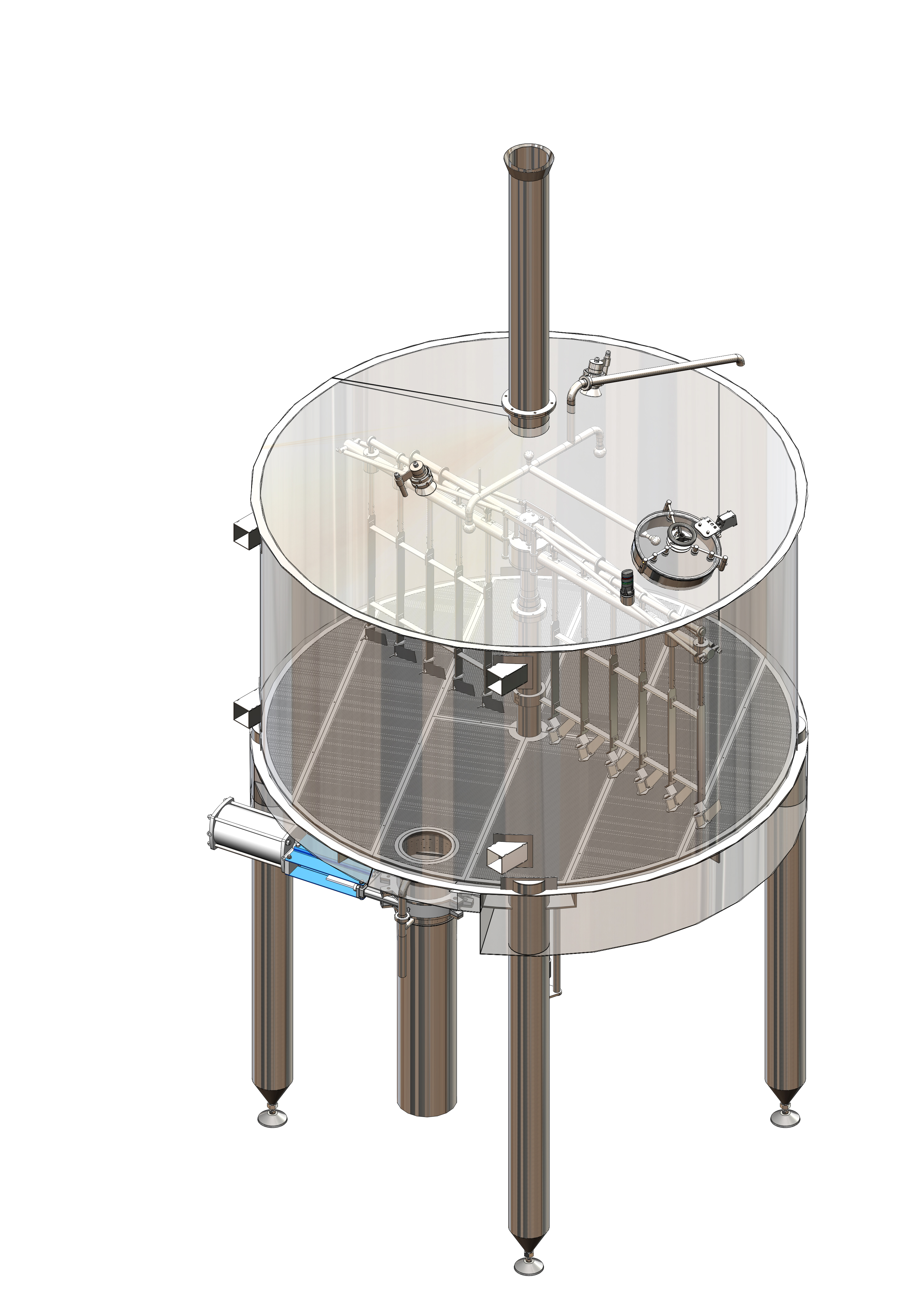

However, comparing to the restaurant mini-breweries, these variants differ in more than just in the type of brewery set jacketing. The brewery set of an industrial mini-brewery can be made in three-vessel or six-vessel variant. Thus, the six-vessel brewery set consists of six separate stainless steel tanks, namely a wort kettle, pre-mash kettle, mash kettle, malt container, filter tank and whirlpool. The industrial variants of our breweries are equipped with a service platform with stairs, a sink with sample cooling and a touch screen for semi-control or full automation of the brewery set. However, in the case of large six-vessel brewery set, we recommend choosing a full-automatic version.

Although called "industrial", even the six-vessel brewery set is, by its design, an adornment of the entire mini-brewery. The exterior jacketing can be made out of ground or polished stainless steel and together with all-glass inlets in all of the six tanks, it creates a pleasant design contrast to the rest of the technology. This statement is best confirmed by already existing mini-breweries of our production such as the Frau Marta Brewery in Rostov-on-Don, Russia, or Gellert Brewery in Astrakhan, Russia

Like all other types of our brewery set, the six-vessel industrial ones are able to brew both in decoction and infusion methods, and therefore, they are able to produce both, the classic double-mash Pilsen lager or the top-fermented specials such as APA, IPA etc.

The duration of one batch is from 8 (infusion) to 11 hours (decoction – double-mash). The six-vessel brewery set can produce up to 6 batches in 24 hours.

CRAFT VERSION

Both types of our industrial brewery set can be adapted to the needs of brewing today's very popular Craft beers. These types of beers are more difficult especially because of their higher alcohol volume and they put a little different demands on the brewery set than the classic Pilsen type of beer.

Therefore, the CRAFT version of our industrial brewery set contains several changes to the standard version, namely:

1) Electric lifting of the stirrer blade in the filter tank and that up to 200 mm.

2) Increase of the filter tank capacity by 20% minimally.

3) Special type of the bottom of the filter tank with increased permeability compared to the standard variant.

Various features of the CRAFT version of our industrial brewery set can be combined with the standard type and, therefore, you can come up with a completely unique form of a brewery set tailored to your requirements.

A model example of an industrial mini-brewery with a 2,000-liter six-vessel brewery set and of a production up to 16,000 hl / year

Description of selected model example components:

Two thousand litre version of a brewing set of an industrial mini-brewery. Stainless steel six-vessel brewing set consists of a wort kettle, pre-mash kettle, mash kettle, malt container, filter tank and whirlpool. This brewing set brews up to 2,000 litres of finished beer per batch. The six-vessel brewing set can produce up to 6 batches in 24 hours. The basic form of this brewing set comes in semiautomatic version, in which the pneumatic valves of the steam and water inlet can be controlled from the touch display. The operator can thus set the individual steps of the temperatures at which the brewing set starts the brewing process, as well as he can set the volume of water to be infused. In this semi-automatic version, the rest of the valves is operated manually. In the case of large six-vessel brewing set, we recommend choosing a full-automatic version (AVS-6N).

For the main fermentation, the cylindro-conical tanks with a working volume of 8 000 litres (four batches) are placed in this industrial model example. We are able to produce and deliver the CK tanks in several qualitative designs and with various certificates of pressure vessels (PED, GOST-R), always exactly based on customer’s needs. The standard tanks can be viewed in the Products / Components / Cylindro-conical tanks section.

This insulated, stainless steel container equipped with a cooling spiral serves for storing and cooling the treated brewing water, which is then used to cool the wort in a single-stage wort cooler. During this process the water is heated to approximately 80 °C and after that, it goes straight to the hot water tank, where it is maintained until the brewing process starts.

Stationary sanitation equipment serving to sanitize the system of pipelines and tanks of the mini-brewery. The sanitation unit is equipped with a pump for a circulation of the sanitizing solutions and with three reservoirs – one for lye, one for acid and the last one for sterilized raising water. The vessel is also equipped with its own electric heater for heating the sanitation lye.

The automatic washer and filler of KEG barrels, Sankeg 35, with a capacity of approximately 30 KEGs (50l) per hour. Sankeg 35 is a two-position device where the first position is used to sanitize the KEGs with an alkaline and acidic solution and the other one is used to fill the KEG barrels with a beverage.

The following components are included in this model example of an industrial mini-brewery

| Component | Pcs |

|---|---|

| Malt grinder 600-1000 kg/hour. ROPPI 1 000 | 1 |

| Spiral malt transporter. SDK7 | 1 |

| Water treatment – iron removal and water softener 2500 l/hour. ZOZ26 | 1 |

| Brewing set – industrial, six-vessels 2 000 l. V20PN5T | 1 |

| Wort cooler 2 000 l/hour. CHM20 | 1 |

| Hot water tank 6 000 l. NHV60 | 1 |

| Steam generator, gas. VR250 – 250 kg/hour | 1 |

| Cylindro-conical tank 8 000 l. CKT80 | 10 |

| Cold water tank 6 000 l. ZUPV60 | 1 |

| Ice water tank 4 000 l. ZLV40 | 1 |

| Water cooling unit. VLV125 | 1 |

| Sanitation unit. CIP500 | 1 |

| Yeast regeneration tank - 120 l. RGK120 | 1 |

| KEG sanitation and filling unit - 30keg/hour. Sankeg 35 | 1 |

| Oil-free compressor for sterile air with filter and dryer. KSV60 - 60m3/hour | 1 |

| * The assembly and the assembly material of the brewery is always calculated according to the additional information of the particular project. | |